India has become a world leader in the production and supply of quartz, a mineral that is used in many different industries, from electronics and construction to glass ceramics and countertops. India is becoming a major player in the world market thanks to its vast reserves, cutting-edge processing techniques and expanding clientele of happy domestic and foreign customers.

This blog discusses why India is a reliable source for premium quartz and explains how to find the best manufacturers and suppliers for your company's requirements. Additionally, we will discuss the growing demand for related resources like coal and the industry leaders, including the top coal importers and traders in India.

Why Quartz from India is in High Demand

Quartz is prized for its durability, chemical resistance, and visual appeal, especially in architectural applications like kitchen countertops, flooring, and wall panels. For industries, its thermal stability and electrical properties make it essential in electronics, solar energy, and metallurgy.

What sets Indian quartz apart is:

- Abundant natural reserves, especially in states like Rajasthan, Andhra Pradesh, and Telangana.

- Affordable labor and logistics make production and export more cost-effective.

- Growing expertise in precision cutting, grading, and processing.

- Adherence to international standards, ensuring quality and safety for both domestic and export markets.

As a result, buyers actively seek partnerships with quartz exporters in India who can deliver consistent quality at competitive prices, with efficient supply chains.

Top Qualities of Trusted Quartz Suppliers in India

Not all suppliers offer the same level of reliability or product excellence. Here's what to look for when evaluating quartz suppliers in India:

1. Quality Certifications

Trusted suppliers often carry ISO certifications and comply with BIS or ASTM standards. This ensures that the quartz you're purchasing meets strict specifications for purity, color, particle size, and durability.

2. Variety and Customization

Whether you require quartz for decorative slabs, silica powder for glassmaking, or high-purity quartz for electronic applications, top suppliers in India offer tailored solutions to meet industry-specific needs.

3. Advanced Processing Facilities

Leading manufacturers use modern machinery such as automated sieving, magnetic separators, and high-capacity crushers to produce uniform, contaminant-free quartz.

4. Export and Domestic Supply Expertise

Reliable quartz exporters in India have deep experience in both local distribution and global shipping, ensuring seamless delivery, proper documentation, and responsive customer service.

Major Quartz Production Regions in India

Several Indian states are known for their quartz reserves and well-developed mining and processing infrastructure:

- Rajasthan – The leader in premium-grade quartz slabs and lumps.

- Andhra Pradesh – A major source for quartz powder and granules.

- Telangana – Hosts processing plants with high-efficiency machinery.

- Tamil Nadu & Karnataka – Emerging regions contributing to both raw and engineered quartz production.

These regions house many reputed manufacturers and quartz exporters in India, serving clients across major sectors like construction, ceramics, electronics, and foundries.

Role of Quartz in Modern Industries

Quartz is essential across several sectors, including:

The consistent domestic and global demand has cemented the role of Indian quartz suppliers as key partners in industrial and infrastructure development.

Choosing the Right Quartz Supplier or Exporter

Here’s how to evaluate and choose a trusted quartz supplier:

- Request Samples – Evaluate consistency in quality, color, and granule size.

- Read Client Reviews – Genuine feedback and case studies build confidence.

- Assess Pricing and Lead Time – Ensure transparency in pricing, with clarity on logistics and delivery timelines.

- Check Export Experience – Experienced quartz exporters in India will understand compliance requirements, especially for international shipments.

Collaborating with the right supplier ensures fewer delays, better quality control, and long-term procurement reliability.

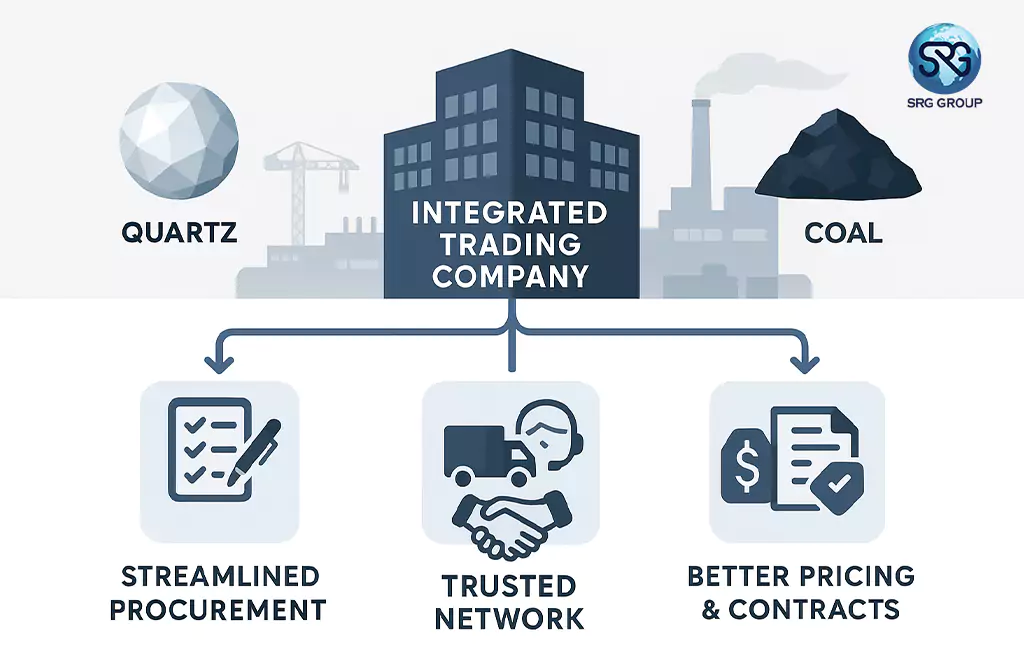

Diversifying Industrial Sourcing: Coal Trading in India

Several mineral suppliers in India deal with energy resources, especially coal, in addition to quartz. Reliable fuel sources are becoming increasingly necessary for the steel, cement and manufacturing sectors in India as the country's industrial output rises.

India's top coal importer and coal trading companies are among the most well-known suppliers of quartz. These businesses oversee the sourcing, distribution, and transportation processes, guaranteeing a steady supply of premium coal to industrial customers nationwide.

Why This Diversification Matters

- Streamlined Procurement – Buy both quartz and coal from one vendor.

- Better Pricing & Contracts – Bulk or bundled deals reduce costs.

- Trusted Network – Integrated logistics and customer support.

With domestic demand for both energy and minerals rising, these integrated trading companies provide efficient, centralized solutions for manufacturers and infrastructure developers.

Conclusion

India’s growing dominance in the quartz market is the result of its rich mineral base, skilled workforce, technological advancements, and commitment to quality. Whether you are in need of silica for glass, high-purity quartz for electronics, or engineered slabs for construction, quartz suppliers in India offer unmatched value.

Moreover, by partnering with companies that also lead as the best coal importer or the best coal trading company, you gain access to a holistic supply network that supports your production and energy needs, right from one source.

In an increasingly competitive global economy, choosing a supplier isn’t just about cost, it’s about trust, reliability, and performance. Indian suppliers deliver on all fronts, making the country a preferred sourcing destination for businesses around the world.